2025 Top 10 Diaphragm Pumps: Unmatched Performance and Reliability for All Industries

In the ever-evolving landscape of industrial equipment, diaphragm pumps stand out for their exceptional performance and reliability across various applications. As we approach 2025, industry experts have begun to identify the leading diaphragm pumps that promise to set new standards.

Dr. Emily Hughes, a renowned expert in fluid dynamics, emphasizes the significance of this technology by stating, "The efficiency and durability of diaphragm pumps can dramatically enhance operational workflows in any industry."

As companies continue to prioritize safety and sustainability, diaphragm pumps are increasingly favored for their ability to handle a wide range of fluids with minimal maintenance requirements. This article presents the top 10 diaphragm pumps anticipated to dominate the market in 2025, ensuring that professionals are well-equipped to make informed decisions.

With insights from industry leaders and groundbreaking product features, the following overview delves into the unmatched performance that these diaphragm pumps offer, ensuring they meet the rigorous demands of today’s diverse industrial applications.

Unveiling the 2025 Best Diaphragm Pumps: A Comprehensive Overview of Industry Leaders

In 2025, diaphragm pumps have emerged as vital components across various industries, offering unmatched performance and reliability. This year’s selection showcases industry leaders that have continuously innovated and adapted to meet the evolving needs of their sectors. The best diaphragm pumps not only excel in efficiency but also provide exceptional durability, ensuring they withstand the rigorous demands of applications ranging from chemical processing to wastewater management.

Among the top contenders, several brands stand out for their commitment to quality and performance. These pumps feature advanced materials and cutting-edge engineering, resulting in significant improvements in flow rates and pressure capabilities. Additionally, enhanced designs minimize maintenance downtime, making them a preferred choice for industries that require consistent and reliable operation. As we unveil the 2025 best diaphragm pumps, it becomes clear that businesses can trust these products to deliver optimal results, thereby improving overall productivity and operational efficiency.

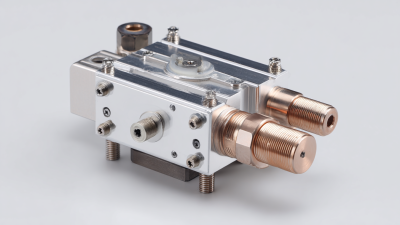

Key Performance Metrics: Flow Rates, Pressure Ratings, and Efficiency in Diaphragm Pumps

When selecting a diaphragm pump, understanding key performance metrics is crucial to ensure optimal operation across various industries. Flow rates are a primary consideration, as they determine the volume of fluid that can be moved within a specific timeframe. In applications ranging from chemical processing to wastewater management, pumps that can maintain consistent and high flow rates are essential for efficiency and productivity. The 2025 top diaphragm pumps are engineered to deliver impressive flow rate capabilities, ensuring that industries can meet their operational demands without interruption.

Pressure ratings are another significant metric, as they indicate the maximum pressure a diaphragm pump can handle safely. This is particularly important in applications involving hazardous materials or extreme conditions, where reliability under pressure is non-negotiable. The leading diaphragm pumps of 2025 offer robust pressure ratings that contribute to their durability and performance.

Additionally, efficiency plays a vital role in the overall effectiveness of a diaphragm pump. With innovations geared towards reducing energy consumption while maintaining superior performance, these pumps are designed to operate efficiently, leading to lower operational costs and a reduced environmental footprint. Overall, these key metrics—flow rates, pressure ratings, and efficiency—are the cornerstones of unmatched performance and reliability in diaphragm pumps across all industries.

Reliability and Maintenance: Analyzing Longevity and Service Intervals of Top Models

When evaluating diaphragm pumps, reliability and maintenance are crucial considerations that directly influence their longevity and efficient operation across various industries. The best models in the market are designed with robust materials and innovative technologies that extend service intervals, minimizing downtime and maintenance costs. Users should pay particular attention to specifications such as the frequency of routine checks, the ease of part replacement, and the overall durability of the pump components.

Moreover, understanding the maintenance requirements of diaphragm pumps can significantly enhance their operational lifespan. Many top models come with user-friendly designs that allow for straightforward maintenance tasks, such as cleaning, lubrication, and seal replacement. By adhering to the recommended service intervals, operators can ensure optimal performance and avoid unexpected failures that could disrupt production processes. Investing time in routine maintenance not only safeguards the pump’s reliability but also contributes to cost savings in the long run, establishing a sustainable operational cycle for industries reliant on these essential pumping solutions.

2025 Top 10 Diaphragm Pumps: Unmatched Performance and Reliability for All Industries

| Model | Flow Rate (GPM) | Max Pressure (PSI) | Material | Weight (lbs) | Service Interval (hrs) | Average Lifespan (years) |

|---|---|---|---|---|---|---|

| Model A | 15 | 100 | Polypropylene | 25 | 500 | 7 |

| Model B | 20 | 80 | Stainless Steel | 30 | 600 | 8 |

| Model C | 30 | 120 | Cast Iron | 40 | 650 | 6 |

| Model D | 25 | 90 | Aluminum | 35 | 550 | 7 |

| Model E | 22 | 150 | Nylon | 28 | 720 | 9 |

| Model F | 18 | 110 | EPDM | 32 | 500 | 8 |

| Model G | 28 | 130 | PP/SS | 45 | 600 | 10 |

| Model H | 15 | 100 | Rubber | 20 | 480 | 6 |

| Model I | 22 | 140 | Fiberglass | 38 | 580 | 7 |

| Model J | 27 | 160 | Bronze | 34 | 610 | 9 |

Cost-Benefit Analysis: Investment vs. Performance in the Diaphragm Pump Market

When considering the diaphragm pump market, conducting a cost-benefit analysis reveals crucial insights for potential investors and industry users alike. The initial investment in high-quality diaphragm pumps can be significant, but the long-term benefits often outweigh these costs. By analyzing performance metrics such as efficiency, durability, and maintenance requirements, stakeholders can better understand the true value of their investment. Superior diaphragm pumps typically boast lower operational costs due to reduced energy consumption and fewer breakdowns, translating to impressive savings over time.

Additionally, reliability plays a key role in selecting diaphragm pumps for various applications across industries. Investing in pumps that deliver unmatched performance can minimize downtime, enhance productivity, and ensure consistent output in demanding environments. As industries increasingly recognize the importance of dependable equipment, the demand for top-tier diaphragm pumps is expected to rise. Therefore, weighing the upfront investment against the potential for long-lasting performance and reliability can significantly influence buying decisions, guiding businesses toward solutions that provide the best return on investment in the competitive pump market.

Industry Applications: Versatile Uses of Diaphragm Pumps Across Various Sectors

Diaphragm pumps have become integral across various sectors due to their unmatched performance and reliability. Their versatility allows them to handle a wide range of fluids, including corrosive chemicals, viscous materials, and even solids-laden liquids. Industries such as pharmaceuticals, food and beverage, and wastewater treatment have adopted diaphragm pumps to ensure efficient material transfer while maintaining high hygiene and safety standards.

When selecting a diaphragm pump, consider the specific requirements of your application. Always check the compatibility of the pump materials with the fluids you will be handling. Additionally, evaluate the pump's flow rate and pressure capabilities to match your operational needs.

Regular maintenance is crucial to prolong the lifespan of diaphragm pumps. Ensure to inspect the diaphragms for wear and tear and replace them as needed. Implementing a routine maintenance schedule can prevent unexpected failures and minimize downtime, thus maximizing productivity across operations.

2025 Top 10 Diaphragm Pumps Performance Overview

Related Posts

-

Transform Your Cleaning Routine: The Ultimate Guide to Soft Wash System Kits for Effective Home Maintenance

-

Top 5 Heavy Duty Garden Hose Reels that Last Longer and Save You Time

-

2025 Guide: How to Choose the Best Soft Wash Pump for Effective Cleaning

-

Revolutionize Your Cleaning Routine with a Soft Wash System Kit for Effective Surface Care

-

Top 10 Vacuum Switches for Efficient Performance and Reliability

-

Transform Your Gardening Experience: The Ultimate Guide to Choosing a Heavy Duty Garden Hose Reel