Top 10 Tips for Choosing the Right Electric Diaphragm Pump for Your Needs

Choosing the right electric diaphragm pump for your specific applications can be a daunting task, especially with the myriad of options available in the market today. As John Smith, an industry expert with over 20 years of experience in fluid transfer systems, aptly puts it, "The right electric diaphragm pump can significantly enhance operational efficiency and reduce maintenance costs." This statement underscores the importance of making an informed decision when selecting a pump that fits your needs.

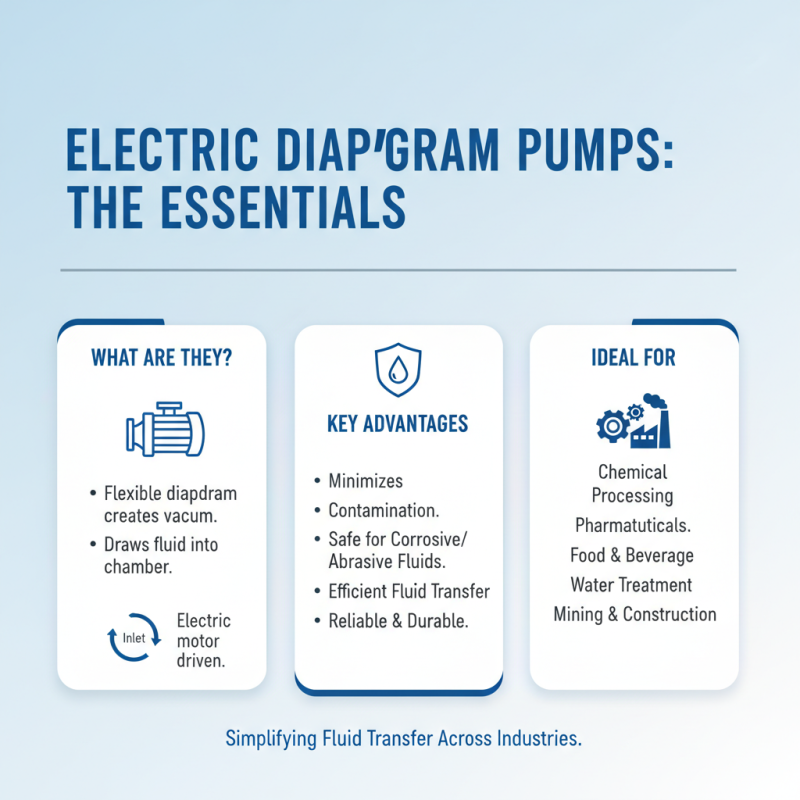

When considering the variety of electric diaphragm pumps, it's crucial to take into account factors such as material compatibility, flow rate requirements, and power options. The diverse applications of these pumps, ranging from chemical processing to food and beverage industries, require careful assessment to ensure optimal performance. By understanding the critical aspects of electric diaphragm pumps, users can avoid the pitfalls that arise from a hasty choice and benefit from the reliability and efficiency these systems offer.

In the following sections, we will explore the top 10 tips that can guide you in making an educated decision about the electric diaphragm pump best suited for your operations. These tips are designed to empower users, whether they are new to the industry or seasoned professionals, to select a pump that aligns with their operational demands and helps streamline their processes.

Understanding the Basics of Electric Diaphragm Pumps

Electric diaphragm pumps are integral components across various industries, providing a reliable solution for transferring fluids safely and efficiently. Understanding the basics of these pumps helps streamline the selection process. Unlike traditional mechanical pumps, electric diaphragm pumps utilize a flexible diaphragm, which changes shape to create a vacuum that draws fluid into the pump chamber. This design minimizes contamination risks and is particularly advantageous in handling corrosive or abrasive liquids.

In the global market, electric diaphragm pumps are anticipated to see a compound annual growth rate (CAGR) of 6.2% from 2020 to 2027, indicating their growing adoption across sectors like water treatment, agriculture, and pharmaceuticals. Furthermore, according to a report by Grand View Research, the increasing requirements for efficient liquid transfer in various applications are driving innovations in diaphragm pump design and technology. Understanding fluid properties, flow rates, and system pressure requirements are essential factors when selecting the right pump to ensure optimal performance and longevity.

Key Factors to Consider When Choosing a Pump

When selecting the right electric diaphragm pump, several key factors should guide your decision-making process. First and foremost, consider the pump’s flow rate and pressure. Understanding the specific flow and pressure requirements of your application is crucial because it ensures optimal performance and efficiency. An undersized or oversized pump can lead to operational issues, including reduced efficiency or premature wear.

Look for pumps with adjustable settings to accommodate changes in your process.

Another essential factor is the materials used in the construction of the pump. The choice of material directly affects the pump's compatibility with various fluids and the overall durability of the system. For instance, if you are handling aggressive chemicals, pumps made from corrosion-resistant materials are necessary to prevent degradation over time. Additionally, evaluate the pump's maintenance requirements and ease of access for repairs, as these can greatly impact operational downtime and overall cost efficiency.

Evaluating the Flow Rate and Pressure Requirements

When selecting an electric diaphragm pump, understanding your specific flow rate and pressure requirements is crucial for optimal performance. According to industry reports, efficient pumps typically operate within a flow rate of 1 to 100 GPM (gallons per minute), and the ideal flow rate is determined by the particular application, whether it be chemical transfer, water treatment, or food processing. Evaluating the specific demands of your application can significantly impact efficiency and cost-effectiveness.

Tip: Assess your application's maximum flow demands while factoring in any potential fluctuations. This will guide you in selecting a pump that not only meets current needs but can also adapt to future requirements.

Additionally, pressure capability plays a vital role in pump selection. Most diaphragm pumps function effectively at pressures ranging from 5 to 100 PSI, but understanding the maximum pressure needed for your application is essential. A pressure that is too low may not adequately move the fluid through the system, while excessive pressure can lead to pump failure or inefficiency.

Tip: Always consult manufacturer specifications to get insights on pressure ratings and ensure that the selected pump can handle the necessary operational stress. This comprehensive evaluation of flow rates and pressure is fundamental in making an informed decision that aligns with your operational needs.

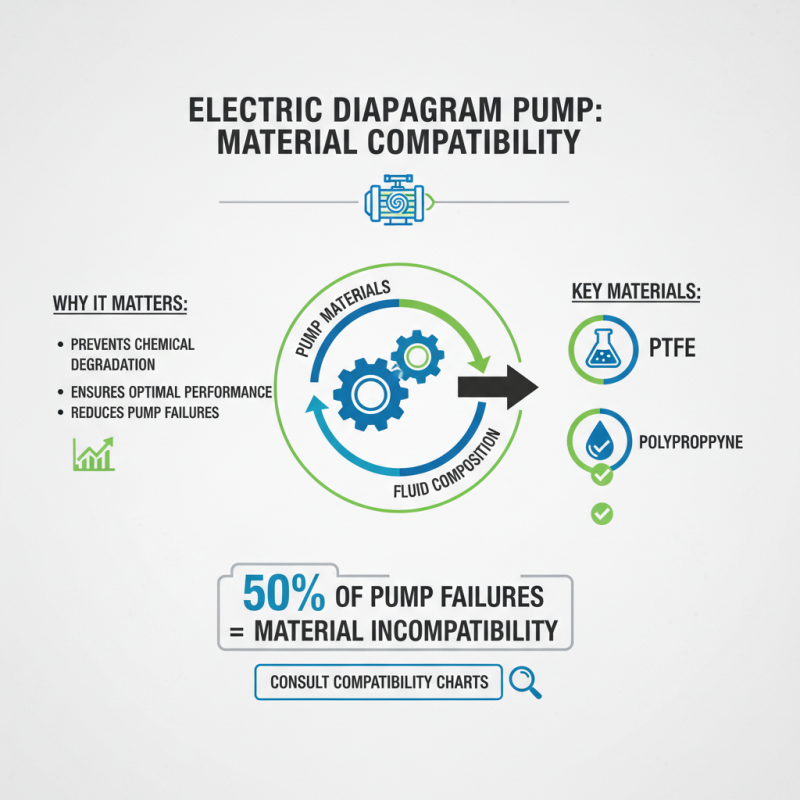

Material Compatibility and Durability Considerations

When selecting an electric diaphragm pump, one of the most critical factors to consider is material compatibility. The pump’s construction materials must align with the fluids it will handle to prevent chemical degradation and ensure optimal performance. For instance, according to a report by the Chemical Processing Industry, nearly 50% of pump failures are attributed to material incompatibility. Thus, understanding the chemical composition of the media is essential. It is advisable to consult compatibility charts or technical data sheets provided by manufacturers to identify suitable materials, such as PTFE or polypropylene, which are known for their chemical resistance.

Durability is equally important when choosing a diaphragm pump. The pump should withstand not only the chemical characteristics of the media but also the operating conditions, including pressure and temperature. A study highlighted by the American Society of Mechanical Engineers indicates that pumps designed with reinforced materials can enhance lifespan and reduce maintenance costs by up to 30%. Therefore, when evaluating pumps, prioritize those that offer robust construction and materials that can endure harsh environments.

Tip: Always inquire about the expected lifespan and maintenance requirements of the diaphragm pump you are considering. A well-documented maintenance plan can significantly extend the utilization period of your equipment, ensuring that your investment is sound and reliable in the long run. Additionally, assessing customer feedback on durability can provide insights into the real-world performance of the pump.

Maintenance and Serviceability of Diaphragm Pumps

When selecting an electric diaphragm pump, it is essential to consider not only performance specifications but also maintenance and serviceability. A well-designed diaphragm pump should allow for easy access to its components, making routine inspections and service tasks more manageable. Look for pumps that feature tool-free disassembly or modular design, which can significantly reduce downtime during maintenance. Ensuring that spare parts are readily available and easy to replace is also crucial, as this will minimize disruptions to operations.

Regular maintenance is key to prolonging the lifespan of diaphragm pumps. This includes periodic checks on diaphragm wear, seals, and other moving parts. A good pump should come with clear maintenance guidelines that outline recommended service intervals and proper upkeep procedures. Additionally, consider whether the pump design facilitates proper cleaning and inspection, especially if it will handle various fluids. A pump that is easy to maintain will not only save time and money but also ensure consistent performance and reliability in critical applications.

Maintenance and Serviceability of Diaphragm Pumps

This chart illustrates the average maintenance requirements and serviceability scores of different types of electric diaphragm pumps based on key performance factors.

Related Posts

-

10 Essential Tips for Choosing the Right Diaphragm Water Pump for Your Needs

-

2025 Top 10 Electric Hose Reels: Elevate Your Gardening Game

-

2025 Top 10 Diaphragm Pumps: Unmatched Performance and Reliability for All Industries

-

The Ultimate Guide to Choosing the Right Hose Reel for Your Garden Setup

-

Understanding the Mechanics of Piston Pumps: A Deep Dive into Their Applications and Innovations

-

Unlocking Efficiency: How Triplex Pumps Transform Industrial Fluid Management