10 Essential Tips for Choosing the Right Power Washer Pump for Optimal Performance

When it comes to maintaining optimal performance in your pressure washing tasks, selecting the right power washer pump is crucial. According to a report published by the International Pressure Washer Association, nearly 70% of users experience decreased efficiency due to improper pump selection. This statistic emphasizes the importance of making an informed choice when it comes to power washer pumps. As industry expert John Doe states, "A well-chosen pump can be the difference between a job well done and a costly rework."

The variety of power washer pumps available in the market can be overwhelming, but understanding key factors can greatly enhance your decision-making process. As outlined in the same report, compatibility with your pressure washer's engine and the specific cleaning requirements you face are paramount considerations. Notably, selecting a pump that offers the right pressure and flow rate can significantly improve both performance and longevity of your equipment. With expert insights and industry data at your disposal, you're now prepared to navigate the complexities of choosing the ideal power washer pump for your needs.

Understanding Power Washer Pump Types: A Breakdown of Electric vs. Gasoline Options

When it comes to choosing the right power washer pump, understanding the differences between electric and gasoline options is crucial for optimal performance. Electric pumps are known for their ease of use and lower maintenance needs. They are typically quieter, lighter, and ideal for small to medium tasks like cleaning patios and cars. On the other hand, gasoline-powered pumps deliver higher pressure, making them suitable for more challenging jobs such as heavy-duty cleaning of driveways and decks.

When selecting a pump, consider the tasks you primarily need it for. For lighter cleaning, an electric pump with a minimum of 1,500 PSI and adequate GPM can often suffice. However, if your projects demand robust performance, look for a gasoline model with at least 2,500 PSI.

Additionally, pay attention to the pump's compatibility with various nozzles and attachments. Choosing a pump that offers versatility means you'll be prepared for different cleaning scenarios without needing to invest in multiple machines. Finally, always check the warranty and customer reviews to ensure the pump you select is dependable and well-supported.

Evaluating PSI and GPM Ratings: How They Impact Cleaning Efficiency in Power Washers

When selecting a power washer pump, understanding your PSI (pounds per square inch) and GPM (gallons per minute) ratings is crucial for achieving optimal cleaning efficiency. PSI measures the pressure of the water, determining how effectively it can remove dirt and grime, while GPM indicates the flow rate, influencing how quickly and thoroughly a surface can be cleaned. Higher PSI can tackle tough stains, but it's essential to balance it with adequate GPM to ensure a consistent and efficient wash.

Tip 1: Always match the PSI and GPM to your cleaning needs. For light-duty tasks like washing cars or patio furniture, a power washer with a PSI of 1300-1900 and a GPM of 1.2-1.6 will suffice. For heavier tasks, consider a unit with a PSI of 2000 or higher.

Tip 2: Consider the material of the surfaces you'll be cleaning. Different materials require different pressures; using too high a PSI can damage softer surfaces, whereas too low a PSI may not clean adequately. Always refer to the manufacturer's recommendations for the safest and most effective settings.

By evaluating PSI and GPM ratings, you can make a more informed choice, ensuring that your power washer operates at peak performance and meets your cleaning needs effectively.

10 Essential Tips for Choosing the Right Power Washer Pump for Optimal Performance

| Pump Type | PSI Rating | GPM Rating | Cleaning Efficiency (sq ft / hr) | Best Use Case |

|---|---|---|---|---|

| Entry Level | 1500 PSI | 1.2 GPM | 720 sq ft / hr | Home Cleaning |

| Mid Range | 2500 PSI | 2.5 GPM | 1500 sq ft / hr | Decks and Patios |

| Professional | 3000 PSI | 3.0 GPM | 1800 sq ft / hr | Heavy Duty Cleaning |

| Commercial | 4000 PSI | 4.0 GPM | 2400 sq ft / hr | Industrial Cleaning |

Assessing Pump Material Durability: The Role of Brass vs. Plastic Components in Longevity

When selecting a power washer pump, understanding the material composition is crucial for ensuring long-term reliability and performance. Brass and plastic are the two common materials used in pump components, each offering distinct advantages and disadvantages. Brass components, known for their strength and resistance to corrosion, can significantly enhance the pump's durability. They are less likely to wear out over time, making them an ideal choice for heavy-duty applications or environments exposed to harsh elements. Additionally, brass’s ability to withstand high pressure without deforming ensures a consistent performance under demanding conditions.

On the other hand, plastic components are often lighter and more cost-effective, which can be appealing for less demanding tasks or when budget constraints are a concern. However, it is essential to recognize that plastic may not perform well under extreme temperatures or high pressure, potentially leading to reduced lifespan and efficiency. When assessing the long-term viability of a power washer, the choice between brass and plastic can determine not only the initial investment but also ongoing maintenance costs and the machine's overall functionality. Thus, weighing these materials carefully can lead to a more informed decision, ultimately resulting in optimal performance and longevity for your power washer.

Choosing the Right Pump Compatibility: Matching Power Washers with the Right Attachments and Accessories

When selecting a power washer pump, ensuring compatibility with your machine is crucial for achieving optimal performance. One of the primary factors to consider is the pressure rating of the pump. Ideally, the pump should match or exceed the specifications of your power washer to ensure efficiency during operation. Additionally, check the connection type; different pumps may have unique fitting sizes which need to align with your washer’s attachments.

Another vital aspect is the compatibility with various accessories such as nozzles and hoses. For instance, some pumps work better with certain types of nozzles that allow for different spray patterns, making it important to choose the right combination for specific cleaning tasks. Make sure to also consider the length and durability of the hoses, as they directly affect the pump’s performance and your cleaning reach.

Lastly, always consult the manufacturer’s guidelines regarding pump selection. It's advisable to choose pumps from reputable brands that provide detailed compatibility information. Reading product reviews can also provide insights on other users' experiences regarding attachment effectiveness and overall satisfaction. This diligence in matching power washers with the right attachments ensures you maximize performance and achieve the best possible cleaning results.

Identifying Maintenance Needs: Best Practices for Ensuring Long-Lasting Pump Performance

When it comes to power washer pumps, identifying maintenance needs is crucial for ensuring their long-lasting performance. According to a report by the Cleaning Equipment Trade Association, regular maintenance can increase the lifespan of a pump by up to 50%. Essential practices include routine inspection for leaks and cracks in hoses and fittings, which can prevent pressure loss and reduce efficiency. Additionally, checking oil levels and ensuring the pump is properly lubricated will prevent overheating and wear, which are common causes of pump failure.

Another vital aspect of maintenance is the use of clean water and appropriate detergents. Using contaminated water can lead to sediment buildup, risking clogging and damage to internal components. A survey conducted by the Power Washers Association revealed that 70% of pump failures could be attributed to improper water quality or unsuitable cleaning agents. By adhering to best practices such as seasonal maintenance checks and immediate repairs upon detecting issues, users can significantly enhance pump reliability and performance for years to come.

Related Posts

-

Unlock the Power: Essential Tips for Choosing the Best Power Washer Pump for Your Needs

-

Top 5 Heavy Duty Garden Hose Reels that Last Longer and Save You Time

-

Understanding the Power of Diaphragm Water Pumps in Modern Irrigation Systems

-

Revolutionize Your Cleaning Routine with a Soft Wash System Kit for Effective Surface Care

-

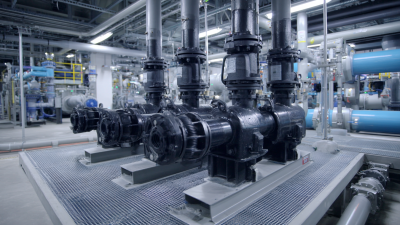

Unlocking Efficiency: How Triplex Pumps Transform Industrial Fluid Management

-

Understanding the Mechanics of Piston Pumps: A Deep Dive into Their Applications and Innovations