How to Efficiently Pump Oil Without Compromising Quality and Safety

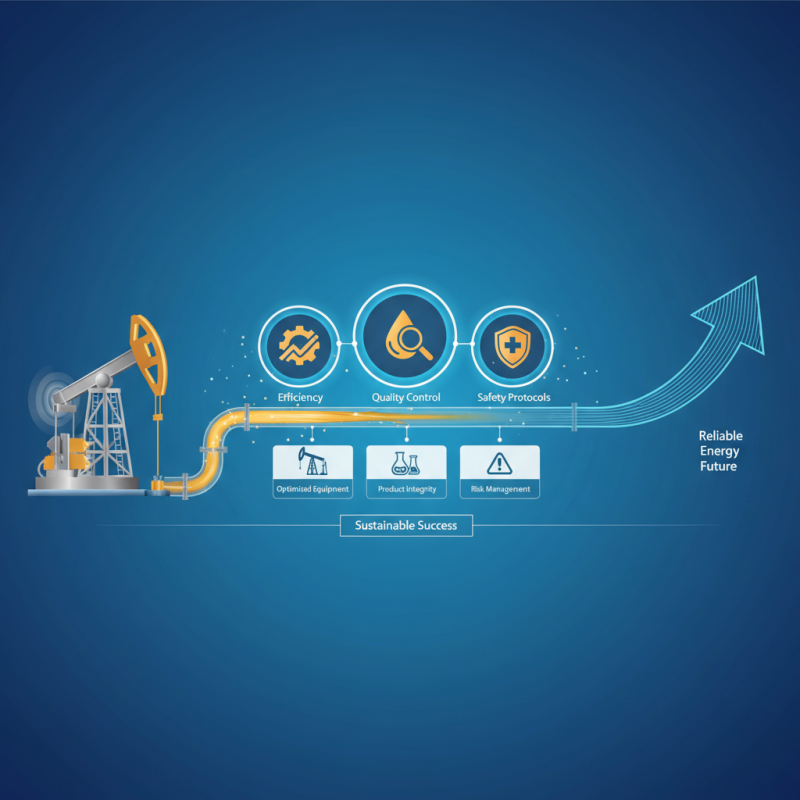

In the dynamic world of oil production, the process of efficiently pumping oil has emerged as a critical focus for industry professionals. As the demand for energy continues to rise, optimizing oil pumping methods while maintaining quality and safety standards is essential. The challenge lies not only in maximizing the volume of oil extracted but also in ensuring that the integrity of the product remains uncompromised throughout the operation.

Effective oil pumping is influenced by several factors, including equipment selection, operational practices, and adherence to safety protocols. By prioritizing these elements, companies can enhance their pumping efficiency, resulting in increased productivity and reduced operational costs. Moreover, implementing best practices in pumping techniques fosters a safer work environment, minimizing risks associated with oil extraction and transportation.

As the oil industry navigates the complexities of modern challenges, a strategic approach to pumping oil can serve as a pathway to sustainable success. This introduction sets the stage for exploring innovative methodologies and practices that enable industry stakeholders to pump oil efficiently while safeguarding quality and safety—ensuring a reliable energy future.

Best Practices for Oil Pumping Operations

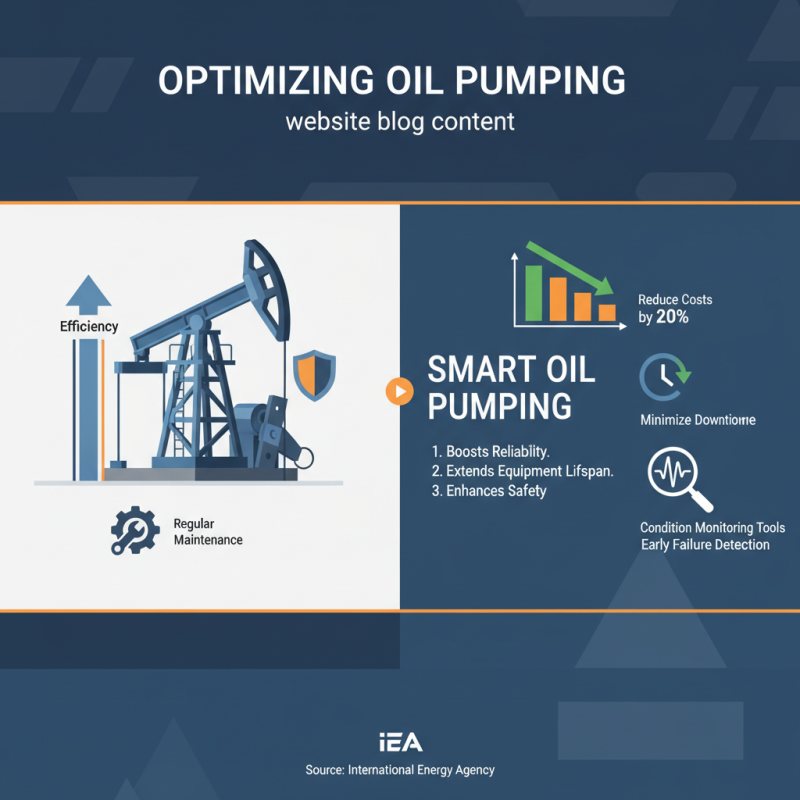

Oil pumping operations require meticulous attention to both efficiency and safety to ensure high-quality output. According to the International Energy Agency (IEA), optimizing oil pumping can lead to a reduction in operational costs by up to 20%. One of the best practices is to implement regular maintenance schedules for pumps and related infrastructure. This practice not only improves the reliability of the equipment but also extends its lifespan. The use of condition monitoring tools can help operators identify potential failures early, minimizing unscheduled downtime and enhancing safety measures during operations.

In addition to maintenance, the training of personnel plays a crucial role in the efficiency of oil pumping operations. A study by the American Petroleum Institute (API) revealed that properly trained employees in oil extraction and pumping processes can significantly reduce accidents and spills, ultimately preserving the quality of the oil being pumped. Scheduled training sessions focusing on safety protocols, equipment handling, and emergency procedures can empower workers to respond effectively to any challenges that may arise. Furthermore, employing automated systems can help streamline operations, reduce human error, and maintain consistent quality of the pumped oil. These combined strategies not only enhance productivity but also ensure a commitment to safety and quality.

Understanding Oil Quality and Safety Standards

In the oil industry, maintaining high-quality standards while ensuring safety during the pumping process is crucial. According to the American Petroleum Institute (API), oil quality is primarily measured through its physical and chemical properties, including viscosity, density, and sulfur content. These parameters are vital for determining the suitability of oil for various applications and its compliance with safety regulations.

A recent report by the International Energy Agency (IEA) states that approximately 40% of oil produced globally does not meet the desired quality standards, leading to potential risks during transportation and refining.

To adhere to safety protocols, industries must implement strict quality control measures throughout the pumping process. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of establishing a comprehensive safety management system that includes regular assessments of equipment and adherence to best practices.

For instance, ensuring that pumps are adequately maintained and using pressure monitoring devices can mitigate risks associated with leaks or spills. Studies indicate that facilities that prioritize both quality and safety can achieve a 15% reduction in operational hazards, thereby fostering a safer work environment while ensuring the integrity of the oil being processed.

Investing in technology such as advanced monitoring systems and regular staff training can significantly enhance both quality assurance and safety compliance. The transition towards automation and real-time data analytics is projected to lead to a 25% improvement in performance efficiency based on data forecasts from the World Petroleum Council. By focusing on these quality and safety standards, the oil industry can effectively balance efficient pumping practices with the necessary precautions to protect both their products and their workforce.

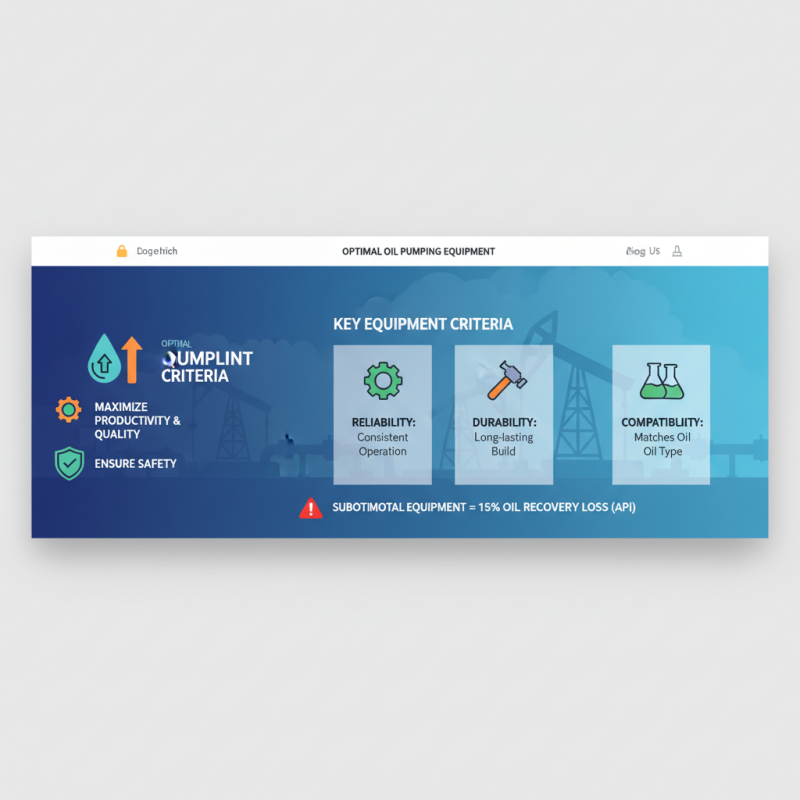

Choosing the Right Equipment for Efficient Oil Pumping

Choosing the right equipment for efficient oil pumping is crucial not only for maximizing productivity but also for ensuring the quality and safety of oil during the extraction process. According to the American Petroleum Institute (API), suboptimal equipment can lead to significant operational inefficiencies, potentially causing losses of up to 15% in oil recovery. To address these concerns, operators should prioritize equipment that offers reliability, durability, and compatibility with the specific characteristics of the oil being pumped.

One of the key factors in selecting pumping equipment is understanding the viscosity and chemical composition of the oil. For example, lighter oils may require centrifugal pumps, which provide high rates of flow with minimal energy consumption, while heavier oils often necessitate positive displacement pumps to maintain consistent pressure and flow rates. The American Society of Mechanical Engineers (ASME) reports that using the correct pump type can reduce energy expenditure by as much as 30%, further highlighting the importance of equipment choice. Additionally, integrating automation and monitoring systems can enhance safety by allowing for real-time assessment of equipment performance and oil quality, thereby mitigating risks associated with spills or equipment failure.

Investing in high-quality pumps and related technologies not only improves operational efficiency but also safeguards the integrity of the oil being transported. Regular maintenance and upgrades to the pumping systems based on industry best practices can further ensure compliance with safety standards, reducing the likelihood of accidents that could lead to environmental damage or financial loss. The choice of pumping equipment should thus align with both current operational goals and long-term sustainability objectives.

Monitoring and Maintaining Pipeline Integrity During the Process

Maintaining pipeline integrity is crucial for the efficient pumping of oil, as it minimizes risks associated with leaks and contamination. Regular monitoring using advanced technologies such as smart sensors can provide real-time data on pipeline conditions. These sensors help detect any irregularities in pressure, temperature, and flow rates, allowing for immediate action if problems arise. Additionally, conducting routine inspections and utilizing data analytics can improve the understanding of pipeline performance and integrity.

Tips for maintaining pipeline integrity include implementing a preventive maintenance schedule, which allows for early detection of potential issues before they escalate. Utilize corrosion detection techniques such as ultrasonic testing or magnetic flux leakage, which can effectively identify weaknesses in the pipeline material. Another crucial tip is to ensure that personnel are trained in safety protocols and emergency response. This training helps to prepare workers to react quickly to any incidents, which is essential for minimizing risks during the pumping process.

Finally, investing in a robust communication system for the pipeline operation ensures that all team members stay informed about current conditions and potential risks. Regular updates and open lines of communication foster a proactive approach, significantly enhancing the overall safety and quality of oil pumping operations.

How to Efficiently Pump Oil Without Compromising Quality and Safety - Monitoring and Maintaining Pipeline Integrity During the Process

| Monitoring Aspect | Key Parameters | Importance | Frequency of Monitoring |

|---|---|---|---|

| Pressure Levels | PSI, Flow Rate | Ensures optimal flow and prevents leaks | Every 30 minutes |

| Temperature Monitoring | Temperature in degrees Celsius | Prevents overheating and potential failures | Hourly |

| Leak Detection | Sound level, pressure drop | Critical for environmental safety | Continuously |

| Corrosion Monitoring | Corrosion rate | Maintains pipeline integrity | Monthly |

| Flow Rate Analysis | Gallons per minute | Ensures efficient operation | Daily |

Training Personnel for Safe and Efficient Oil Handling Techniques

Training personnel in safe and efficient oil handling techniques is crucial for optimizing operational productivity while ensuring safety standards are met. A recent report by the American Petroleum Institute highlights that organizations with comprehensive training programs experience up to a 30% decrease in workplace accidents related to oil handling. By equipping employees with the right skills and knowledge, companies can not only protect their workforce but also enhance their operational efficiency, limiting potential downtime caused by incidents.

Effective training should encompass a variety of aspects, including proper equipment handling, spill response procedures, and emergency protocols. According to the Occupational Safety and Health Administration (OSHA), proper training can reduce incidents linked to human error by nearly 40%. Implementing simulations and hands-on practice sessions can significantly improve retention and understanding of safe oil handling practices. Furthermore, regular refresher courses can keep staff updated on industry best practices and evolving safety regulations, ultimately helping to maintain a safe and productive environment in oil pumping operations.

Related Posts

-

Maximizing Efficiency with Industrial Water Hose Reels for Optimal Fluid Management in Manufacturing

-

Transform Your Cleaning Routine: The Ultimate Guide to Soft Wash System Kits for Effective Home Maintenance

-

What Are Titan Hose Reels and How Do They Enhance Your Gardening Experience?

-

How to Choose the Best Commercial Hose Reel for Your Landscaping Needs

-

Unlock the Power: Essential Tips for Choosing the Best Power Washer Pump for Your Needs

-

2025 Guide: How to Choose the Best Soft Wash Pump for Effective Cleaning