How to Choose the Right Electric Diaphragm Pump for Your Needs

In recent years, the demand for electric diaphragm pumps has surged, driven by their versatility and efficiency in various industrial applications. According to the Global Diaphragm Pump Market Report, the market is projected to grow at a CAGR of 6.5% from 2021 to 2026, fueled by the increasing need for reliable fluid transfer systems in sectors such as chemical processing, water treatment, and pharmaceuticals. These pumps are recognized for their ability to handle a wide range of viscosities and corrosive materials, making them essential tools in numerous settings.

Choosing the right electric diaphragm pump for your needs involves a careful evaluation of several key factors, including flow rate, pressure requirements, and compatibility with the fluids being pumped. With the market offering diverse options, a comprehensive understanding of specific application requirements is vital for optimizing performance and ensuring longevity. By assessing these parameters, businesses can make informed decisions that enhance operational efficiency while minimizing maintenance costs. As industry standards evolve, aligning pump selection with specific operational goals becomes increasingly critical for achieving success in an ever-competitive landscape.

Understanding the Basics of Electric Diaphragm Pumps

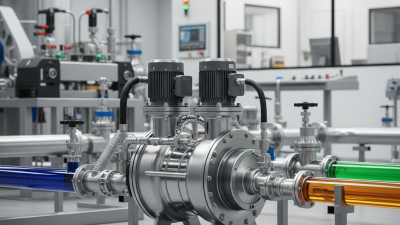

Electric diaphragm pumps are versatile devices widely used in various industries, including chemical processing, water treatment, and food production. Understanding the basics of these pumps is crucial for making an informed purchasing decision. Electric diaphragm pumps operate on the principle of a diaphragm that flexes to create a vacuum, allowing fluids to be drawn into the pump chamber and then expelled. According to a recent market analysis report, the global diaphragm pump market size is expected to reach $6.8 billion by 2025, driven by the growing demand for efficient fluid handling solutions.

When selecting an electric diaphragm pump, several key factors must be considered. Firstly, the fluid characteristics, including viscosity, temperature, and chemical compatibility, significantly influence pump performance. For instance, pumps designed for abrasive or viscous fluids require materials resistant to wear and tear, such as PTFE or other durable composites. Moreover, flow rate and pressure requirements are essential parameters; many applications dictate a specific flow range and pressure settings. Research indicates that pumps with adjustable flow rates can improve operational efficiency by 20-30% in varying conditions.

Another important aspect to consider is the power source and operational efficiency of the pump. Electric diaphragm pumps are increasingly favored over pneumatic options due to their ability to provide consistent power and reduced maintenance requirements. Studies show that electric diaphragm pumps can operate with efficiency ratings exceeding 90%, making them a cost-effective solution for many applications. By understanding these foundational elements, users can make more informed choices that align with their operational needs and project specifications.

Identifying Your Specific Application Requirements

When selecting an electric diaphragm pump, it is crucial to pinpoint your specific application requirements first. Consider the nature of the liquids you will be pumping—are they viscous, corrosive, or abrasive? Understanding the physical and chemical properties of the fluid can significantly influence your choice of materials and pump design. For example, if you're working with corrosive chemicals, a pump made from compatible materials will ensure durability and reduce the risk of leakage.

Tips: Always check the compatibility of the pump materials with your fluids. This can help you avoid costly equipment failures and downtime. Additionally, assess the required flow rate and pressure for your application. Different pumps are designed to handle various flow rates and discharge pressures, so choosing one that meets your operational needs is essential.

Lastly, consider the environment in which the pump will operate. Factors such as temperature, humidity, and space constraints can affect your choice. If the pump will be located in a hazardous area, look for models specifically designed for safety in such environments. Customization options may also be available to tailor the pump to your unique settings.

Tips: Don’t forget to account for maintenance and serviceability when making your selection. A pump that is easy to maintain can save you time and money in the long run.

Evaluating Key Performance Factors and Specifications

When selecting the right electric diaphragm pump for specific applications, evaluating key performance factors and specifications is crucial. One of the primary considerations is flow rate, which typically ranges between 0.1 to 300 gallons per minute (GPM) for most electric diaphragm pumps. According to a recent industry report, pumps with higher flow rates are often necessary for industrial applications, while lower flow rates suffice for laboratory settings. It's also essential to assess the pump's maximum pressure capabilities, commonly ranging from 20 to 150 psi, as this directly impacts the pump's efficiency and suitability for tasks like transferring viscous fluids or handling solids.

Material compatibility is another significant factor, especially when dealing with corrosive or abrasive substances. Many electric diaphragm pumps are constructed from materials such as polypropylene or stainless steel, which enhance durability and resistance to chemical degradation. Industry data indicates that choosing the right material can increase pump lifespan by up to 30% in harsh environments. Additionally, the pump's power consumption and operational noise levels must be examined; with many modern models designed for energy efficiency and quieter operation, the right choice not only lowers costs but also minimizes environmental impact, particularly in sensitive settings. These performance factors collectively ensure that the selected pump effectively meets the operational demands while maintaining reliability and efficiency.

How to Choose the Right Electric Diaphragm Pump for Your Needs - Evaluating Key Performance Factors and Specifications

| Performance Factor | Specification 1 | Specification 2 | Specification 3 |

|---|---|---|---|

| Flow Rate (GPM) | 1.5 | 3.0 | 5.0 |

| Max Pressure (PSI) | 50 | 80 | 120 |

| Diaphragm Material | EPDM | Nitrile | PTFE |

| Power Consumption (W) | 100 | 150 | 200 |

| Weight (lbs) | 10 | 15 | 25 |

Comparing Different Brands and Models in the Market

When choosing the right electric diaphragm pump, it's crucial to compare different brands and models to ensure you find the best fit for your specific applications. Various manufacturers offer pumps with varying specifications, including flow rates, pressure capabilities, and material compatibility. Each of these factors can influence the pump's performance based on your intended use, whether it's for industrial applications, aquariums, or food processing. Assessing the technical parameters and understanding the advantages of each brand can help streamline your decision-making process.

In addition to technical specifications, one must consider the reliability and reputation of the manufacturers. Reading customer reviews and examining performance data can provide valuable insight into how different models perform in real-world situations. Look for feedback regarding durability, maintenance requirements, and customer support services as these aspects can greatly affect long-term satisfaction. By carefully evaluating and comparing the options available, you can make an informed choice that aligns with your operational needs and ensures efficient performance from your electric diaphragm pump.

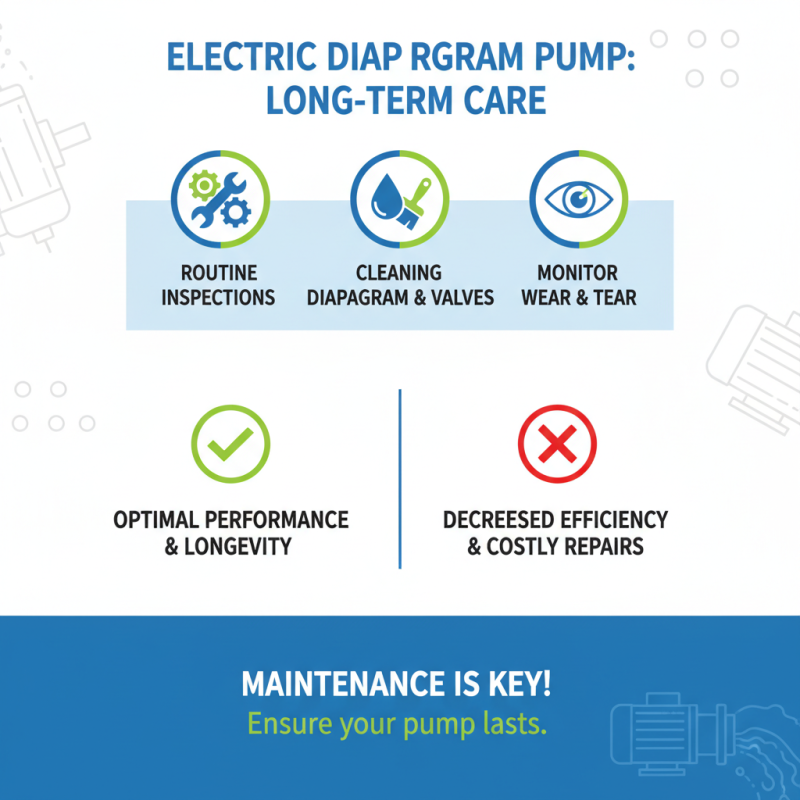

Maintenance and Support Considerations for Long-Term Use

When selecting an electric diaphragm pump, it's essential to consider not only the specifications but also the maintenance and support required for long-term use. Regular maintenance is crucial to ensure optimal performance and longevity of your pump. This includes routine inspections, cleaning of the diaphragm and check valves, and monitoring for any signs of wear and tear. Neglecting these tasks can lead to decreased efficiency and costly repairs down the line.

**Tips**: Always refer to the manufacturer's guidelines for maintenance schedules. Keeping a maintenance log can help you track when inspections are due and identify any recurring issues.

In addition to maintenance, having reliable support is vital. Ensure that you have access to knowledgeable service personnel who can assist with troubleshooting and repairs. It's beneficial to familiarize yourself with the pump’s user manual as it often contains valuable information regarding common problems and their solutions. Having an understanding of the parts and their functions can save time and effort in case of malfunctions.

**Tips**: Establish a relationship with a trusted service provider familiar with your type of pump, as they can provide timely support when needed. Regular training on pump operation and troubleshooting can further empower your team to manage issues effectively.

Related Posts

-

Understanding the Power of Diaphragm Water Pumps in Modern Irrigation Systems

-

10 Essential Tips for Choosing the Right Diaphragm Water Pump for Your Needs

-

Top 10 Tips for Choosing the Right Electric Diaphragm Pump for Your Needs

-

Top Benefits of Using Pneumatic Diaphragm Pumps in 2025 Applications

-

How to Choose the Best Commercial Hose Reel for Your Landscaping Needs

-

2025 Top 5 Soft Wash System Kits for Effortless Exterior Cleaning