2026 Best Pneumatic Pump Options for Your Needs?

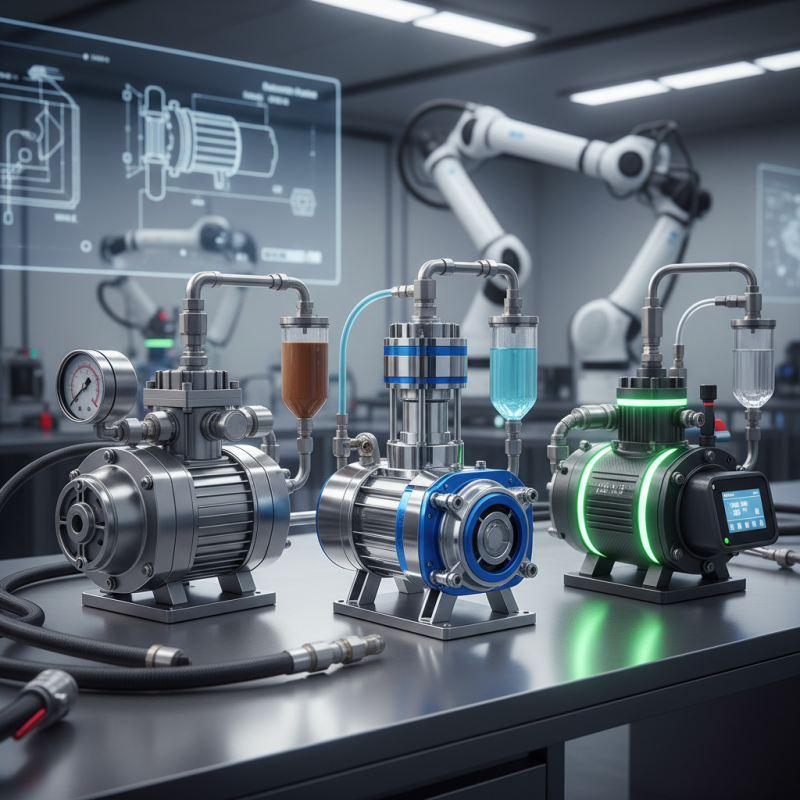

When it comes to choosing the right pneumatic pump, the options can be overwhelming. A pneumatic pump utilizes air pressure to move fluids, making it a versatile tool in various industries. In 2026, advancements in technology have brought forth new options that may cater to different needs and applications.

Selecting the best pneumatic pump requires careful consideration of specific requirements. Factors such as the pump design, capacity, and energy efficiency play a crucial role in performance. Each application has unique challenges. For instance, a construction site may need a robust pump for heavy-duty tasks, while an automotive shop might prefer a compact model for lighter applications. Balancing these needs can be tricky.

Pneumatic pumps are significantly reliable, yet they are not without faults. Users must consider potential maintenance and durability issues. A well-designed pump can reduce downtime, but failures can occur. Reflecting on past experiences can guide future choices. Making informed decisions about pneumatic pumps means understanding both their strengths and weaknesses fully.

Understanding Pneumatic Pumps: Types and Applications

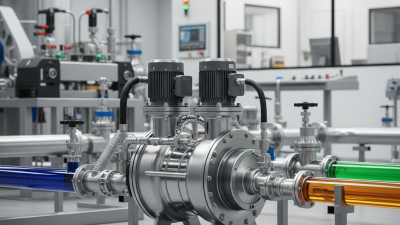

Pneumatic pumps are vital in various industries, from manufacturing to construction. They operate using compressed air, making them efficient and reliable. There are different types of pneumatic pumps, each suited for specific applications. For instance, diaphragm pumps excel in handling corrosive fluids, while piston pumps are ideal for high-pressure applications. According to industry reports, the global pneumatic pump market is expected to reach $6 billion by 2025, reflecting a growing demand across sectors.

The application of pneumatic pumps is diverse. They are commonly used in fluid transfer, spraying, and even in material handling. Their design allows for seamless integration into automated systems, which enhances productivity. However, users must consider factors such as compatibility with the medium and the operating environment. Efficiency can suffer if the wrong type is selected.

**Tip:** Always assess the fluid properties before choosing a pump. This ensures optimal performance and longevity.

Regular maintenance is key. Neglecting maintenance can lead to inefficiencies and increased downtime. It's crucial to monitor air supply quality as contaminants can affect pump performance.

**Tip:** Keep a maintenance log. It helps in tracking performance trends and anticipating issues.

Key Features to Consider When Choosing a Pneumatic Pump

Choosing a pneumatic pump involves careful consideration of several key features. The pump's air consumption is crucial. A pump that consumes too much air can inflate your operational costs. Look for a model that balances performance with efficiency. Also, determine the pump's maximum pressure. You need a pump that meets the demands of your tasks without risking damage.

Tips: Consider the specific application. Not all pumps are suitable for every job. Some may excel in high-volume tasks, while others are better for precision applications.

Another aspect to consider is the maintenance requirements. Some pumps are easier to maintain than others. Check for accessible parts and ease of disassembly. Regular maintenance can prevent costly downtimes. Lastly, weigh the noise levels. A quieter pump can improve your work environment but might come at a higher cost.

Tips: Always review user feedback. Potential users often share valuable insights. Their experiences can reveal strengths and weaknesses you might overlook.

2026 Best Pneumatic Pump Options

This chart shows the estimated flow rate (in liters per minute) of various pneumatic pump types based on their efficiency and recommended applications.

Top Pneumatic Pump Brands and Their Best Models for 2026

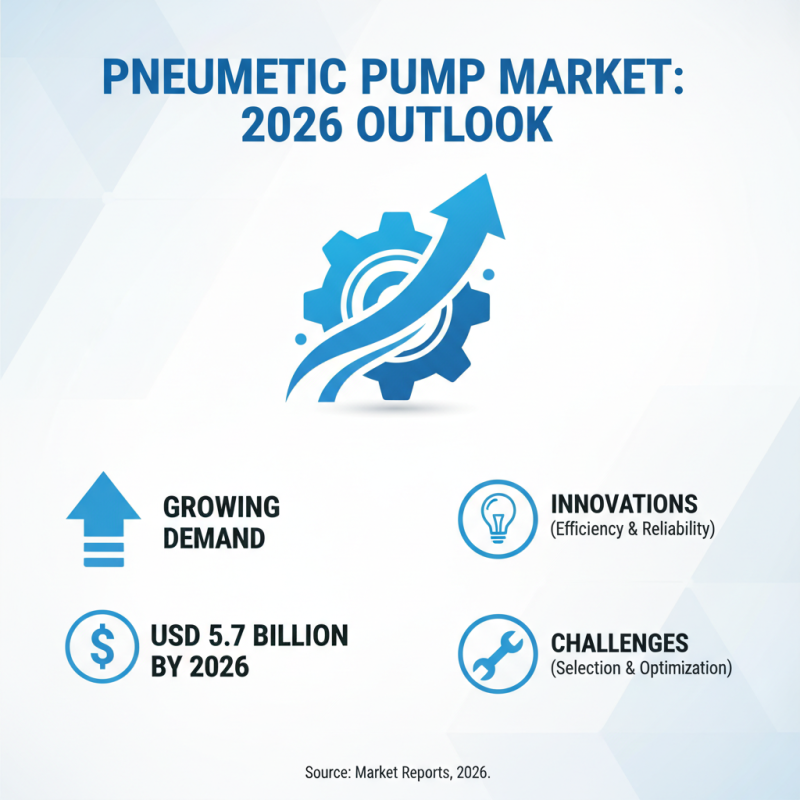

In 2026, the demand for pneumatic pumps continues to grow in various industries. According to recent market reports, the pneumatic pump market is projected to reach USD 5.7 billion by 2026. This growth is driven by innovations in efficiency and reliability, yet challenges remain in pump selection and optimization.

When choosing pneumatic pumps, consider the brand's technological advancements. Some pumps now feature energy-efficient designs, which can reduce operating costs significantly. However, not all models are equal. Certain brands may have inconsistent performance records, particularly in demanding environments. It's crucial to assess user reviews and expert opinions to avoid costly mistakes.

In addition, the size and functionality of the pumps matter greatly. Compact models can save valuable space, but may lack power. Larger pumps offer high capacity, yet they require more maintenance. It's essential to balance performance against these factors. Misjudging your needs can lead to underwhelming results, impacting overall productivity.

Maintenance Tips for Ensuring Optimal Performance of Pneumatic Pumps

Pneumatic pumps are essential for various applications, but they need proper maintenance. Regular care ensures they perform at their best. Here are a few tips to keep your pneumatic pumps in top shape.

One of the most common issues is air leaks. These can lead to inefficiency. Check all connections and seals regularly. Tighten any loose screws or fittings. Listening for hissing sounds can also help identify leaks. Addressing this early can save you time and reduce costs.

Another crucial point is lubrication. Pneumatic pumps need the right amount of oil. Too much or too little can cause problems. Follow manufacturer specifications for lubrication intervals and types. Remember, neglect can lead to wear and reduced performance. Keeping a consistent schedule for checks is a good practice.

Finally, be wary of dust and debris. These can clog filters and affect flow. Clean the pump’s exterior regularly to prevent buildup. Inspect filters and replace them as needed. Developing a routine maintenance plan can prolong the pump’s life and efficiency.

Common Issues and Troubleshooting Techniques for Pneumatic Pumps

Pneumatic pumps are crucial in various industries. However, they often face common issues that require troubleshooting. For instance, air leaks can significantly impact performance. A small gap or a damaged seal can lead to inefficiency. Regularly check connections and seals. This simple step can prevent many problems.

Another frequent issue is loss of pressure. It can occur due to worn-out components or blockages. Inspecting filters and valves regularly is essential. Sometimes, internal parts wear out without visible signs. Catching these problems early can save time and money later.

Users often overlook maintenance. Proper care is critical for the longevity of pneumatic pumps. Neglecting routine checks may lead to malfunction. Familiarizing yourself with the pump's operation can help in identifying odd noises or vibrations. These signs often indicate something is amiss. Don't wait for a complete failure; act early to keep your systems running smoothly.

Related Posts

-

Top 10 Benefits of Using a Pneumatic Pump for Your Industrial Needs

-

Best Diaphragm Pumps for Efficiency and Reliability in 2023

-

Top Benefits of Using Pneumatic Diaphragm Pumps in 2025 Applications

-

Understanding the Mechanics of Piston Pumps: A Deep Dive into Their Applications and Innovations

-

Why Choose a Stainless Steel Hose Reel for Your Outdoor Needs?

-

Top 10 Tips for Choosing the Right Electric Diaphragm Pump for Your Needs