Best Diaphragm Pumps for Efficiency and Reliability in 2023

In the ever-evolving landscape of industrial pumps, diaphragm pumps stand out as a paramount choice for those seeking both efficiency and reliability. Industry expert Dr. Emma Carter, a leading authority in fluid dynamics, emphasizes the importance of diaphragm pumps by stating, "A well-designed diaphragm pump can significantly enhance operational efficiency while minimizing maintenance costs." As we explore the best diaphragm pumps for 2023, it is crucial to understand the unique advantages they offer across various applications, from chemical transfer to water treatment.

With advancements in technology, today’s diaphragm pumps are engineered to meet rising demands, ensuring optimal performance in both low and high-pressure systems. Their versatility and ability to handle a wide range of fluids make them indispensable in many industries. This article will delve into the best diaphragm pumps available this year, assessing their efficiency, durability, and overall reliability. By choosing the right diaphragm pump, businesses can not only improve their operational workflows but also enhance their sustainability efforts.

Overview of Diaphragm Pumps and Their Applications

Diaphragm pumps are a type of positive displacement pump widely recognized for their efficiency and reliability across various industrial applications. These pumps function by using a diaphragm that flexes to create a vacuum and draw fluid in, which is then pushed out through a discharge valve. According to a recent report by the Global Market Insights, the diaphragm pump market is projected to reach USD 5 billion by 2025, growing at an impressive CAGR of 6.5% due to increased demand in sectors such as water treatment, chemicals, and food processing.

One of the key advantages of diaphragm pumps is their ability to handle viscous fluids and slurries without the risk of leakage, making them ideal for industries that require high reliability. For instance, the chemical industry benefits significantly from diaphragm pumps due to their capability to transport corrosive substances safely. A study published in the Journal of Fluid Mechanics highlights that diaphragm pumps maintain operational efficiency in a broad range of pressures, approximately between 0.5 to 8 bar, which is vital for applications where pressure control is critical. This versatility not only enhances operational effectiveness but also reduces the downtime associated with pump maintenance, as diaphragm pumps typically require less frequent servicing compared to other pump types.

Best Diaphragm Pumps for Efficiency and Reliability in 2023

| Model | Max Flow Rate (GPM) | Max Pressure (PSI) | Material | Applications |

|---|---|---|---|---|

| Model A | 10 | 80 | Aluminum | Chemical Transfer |

| Model B | 15 | 100 | Plastic | Water Transfer |

| Model C | 8 | 60 | Stainless Steel | Food Processing |

| Model D | 12 | 90 | Rubber | Oil Transfer |

| Model E | 20 | 120 | Polypropylene | Pharmaceutical |

Key Features of Efficient and Reliable Diaphragm Pumps

When selecting diaphragm pumps for efficiency and reliability, it's essential to focus on key features that define their performance. One crucial aspect is the design of the diaphragm itself. High-quality diaphragms made from durable materials can withstand corrosive substances and ensure a longer lifespan. Additionally, the pump's flow rate is significant; choosing a pump that offers adjustable flow rates can enhance its versatility across different applications, allowing operators to adjust the output according to specific needs.

Tip: Regular maintenance checks can significantly enhance a diaphragm pump's performance. Ensure to inspect the diaphragm for wear and tear periodically, and replace it when necessary to avoid system failures. Additionally, keeping the pump clean and free from contaminants can prolong its efficiency and reliability.

Tip: When installing a diaphragm pump, pay close attention to the orientation and installation of the inlet and outlet connections. Proper positioning can prevent backflow and ensure optimal performance throughout its operational life.

Top Brands and Models for Diaphragm Pumps in 2023

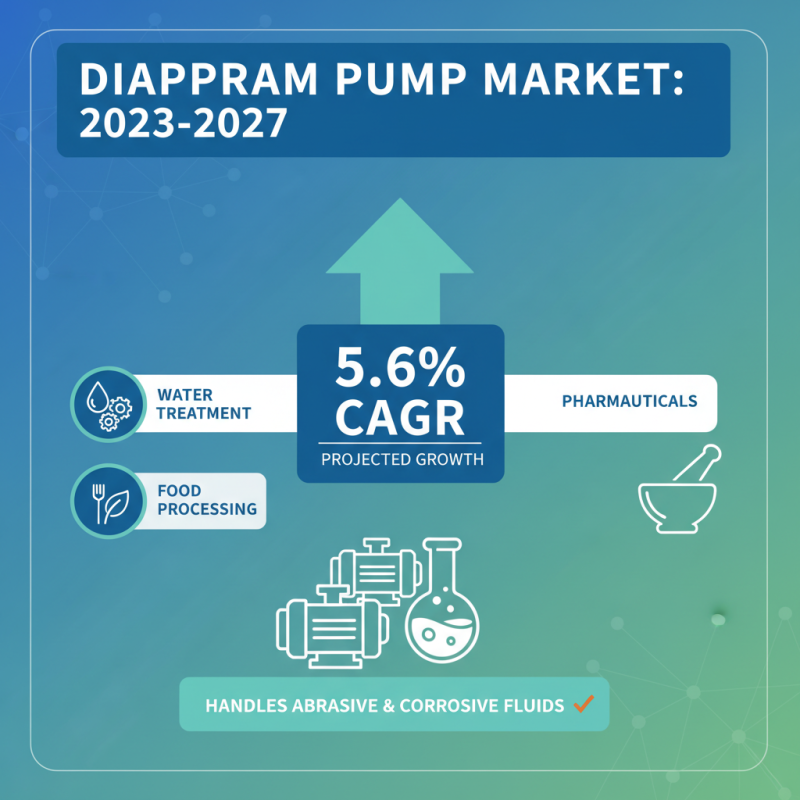

In 2023, the diaphragm pump market has witnessed significant advancements, with various brands competing for the top position by delivering exceptional efficiency and reliability. According to recent industry reports, the diaphragm pump sector is projected to grow at a compound annual growth rate (CAGR) of 5.6% over the next few years, driven by increased demand in sectors such as water treatment, food processing, and pharmaceuticals. These pumps are favored for their ability to handle abrasive and corrosive fluids, making them an indispensable tool across various applications.

Several leading manufacturers have pushed the boundaries of diaphragm pump technology, introducing models that incorporate advanced materials and innovative designs. For instance, many new models utilize reinforced elastomers which enhance longevity and performance while reducing maintenance costs. Furthermore, energy-efficient designs have been prioritized, with reports indicating that the latest pumps can reduce energy consumption by up to 30% compared to their predecessors. This not only lowers operational costs for users but also aligns with sustainability goals highlighted in industry sustainability reports.

Overall, the focus in 2023 has been on optimizing diaphragm pump designs to meet both reliability and efficiency standards. As more sectors recognize the role of diaphragm pumps in improving operational efficiency and reducing downtime, the ongoing investment in technology and design innovation from leading brands is expected to keep transforming the landscape of fluid transfer solutions.

Maintenance Tips for Extended Lifespan of Diaphragm Pumps

Maintaining diaphragm pumps is crucial for ensuring their efficiency and reliability over time. Regular inspection is the first step in effective maintenance. Users should periodically check for leaks, unusual noises, and any signs of wear and tear on the diaphragms and seals. These components are prone to degradation due to constant movement and exposure to various fluids. Addressing these issues promptly can prevent more significant failures that lead to costly repairs or replacements.

Another vital aspect of maintenance is proper lubrication. Ensuring that moving parts are adequately lubricated can reduce friction and wear, resulting in enhanced pump performance. It's also essential to follow the manufacturer's recommendations regarding replacement intervals for diaphragms and other parts. Cleaning the pump regularly helps to remove any contaminants that could affect operation. By implementing these maintenance practices, users can significantly extend the lifespan of their diaphragm pumps, ensuring they remain efficient and reliable for years to come.

Comparative Analysis of Diaphragm Pumps for Various Industries

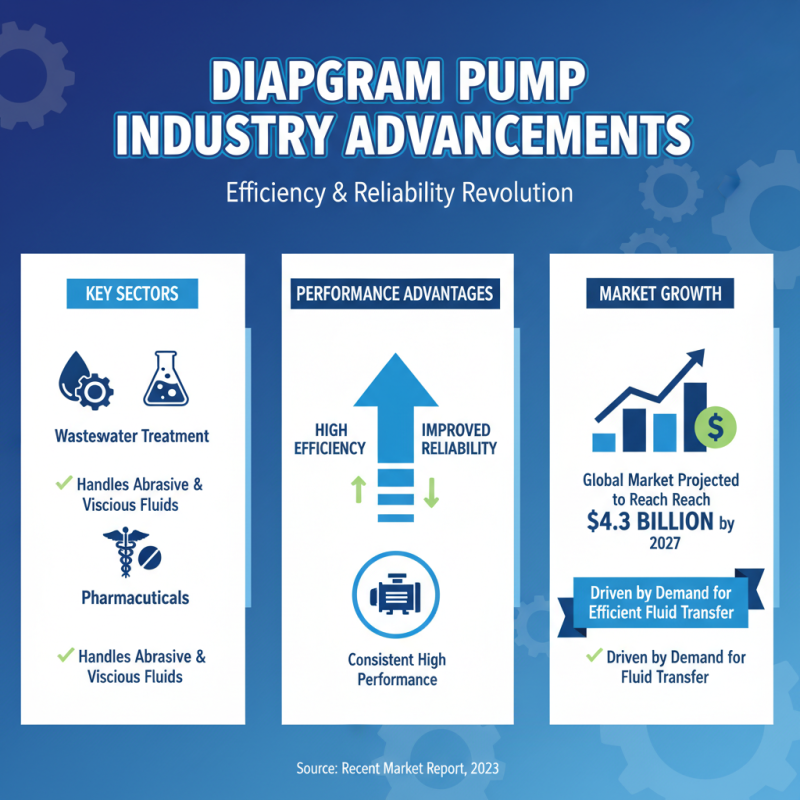

The diaphragm pump industry has seen significant advancements over the years, particularly in terms of efficiency and reliability. An analysis of diaphragm pumps across various sectors—such as wastewater treatment, chemical processing, and pharmaceuticals—demonstrates a growing preference for these pumps due to their ability to handle abrasive and viscous fluids while maintaining high performance. According to a recent market report, the global diaphragm pump market is projected to reach USD 4.3 billion by 2027, driven by increasing demand for efficient fluid transfer solutions.

Industries are increasingly adopting diaphragm pumps because of their operational versatility and maintenance benefits. For instance, in the chemical industry, diaphragm pumps are favored for their leak-free operation, which helps prevent contamination and hazardous spills. A study by the Fluid Handling Association indicated that diaphragm pumps can improve energy efficiency by up to 25% compared to traditional pump technologies. This not only reduces operational costs but also supports environmental sustainability efforts in various sectors.

**Tips**: When selecting a diaphragm pump, consider the fluid's viscosity and the required flow rate to ensure compatibility. Regular maintenance checks and system audits can prolong the pump's life and enhance its reliability. Additionally, investing in pumps with advanced monitoring technology can provide real-time data on performance, enabling proactive management and reducing downtime.

Related Posts

-

2025 Top 10 Diaphragm Pumps: Unmatched Performance and Reliability for All Industries

-

Top 10 Benefits of Using a Pneumatic Pump for Your Industrial Needs

-

Understanding the Power of Diaphragm Water Pumps in Modern Irrigation Systems

-

Transform Your Gardening Experience: The Ultimate Guide to Choosing a Heavy Duty Garden Hose Reel

-

2025 Top 5 Soft Wash System Kits for Effortless Exterior Cleaning

-

What Are Titan Hose Reels and How Do They Enhance Your Gardening Experience?